Cellophane wrapping machines are essential equipment in various industries, particularly in food packaging, pharmaceuticals, and consumer goods. These machines are designed to wrap products in cellophane, a biodegradable and transparent film made from regenerated cellulose. This article will explore the functionality, benefits, and applications of cellophane wrapping machines.

Functionality of Cellophane Wrapping Machines

Cellophane wrapping machines operate by taking a product and enveloping it in a layer of cellophane. The process typically involves several key steps:

1. **Product Feeding**: The machine receives products either manually or automatically from a conveyor belt.

2. **Film Dispensing**: A roll of cellophane film is fed into the machine.

3. **Wrapping**: The machine wraps the product with the film, ensuring a snug fit to protect it from environmental factors.

4. **Sealing**: The edges of the cellophane are sealed, usually with heat or adhesive, to secure the wrap.

5. **Cutting**: The machine cuts the film to the desired length, allowing for efficient wrapping of multiple products in succession.

Modern cellophane wrapping machines come equipped with advanced features such as programmable settings, adjustable wrapping speeds, and sensors to ensure precise wrapping and sealing.

Benefits of Cellophane Wrapping Machines

1. **Eco-Friendly Packaging**: Cellophane is a renewable resource and is biodegradable, making it an environmentally friendly alternative to plastic wraps. Using cellophane can enhance a company's sustainability profile.

2. **Product Protection**: The wrapping provides a barrier against moisture, dust, and contaminants, thereby extending the shelf life of products, especially in the food industry.

3. **Aesthetic Appeal**: The transparent nature of cellophane allows consumers to see the product clearly, enhancing its visual appeal on store shelves.

4. **Cost-Effective**: Automating the wrapping process can significantly reduce labor costs and increase packaging efficiency, allowing businesses to scale up production without a corresponding increase in labor.

5. **Versatility**: Cellophane wrapping machines can handle a variety of products, from food items like candies and baked goods to non-food items like cosmetics and pharmaceuticals.

Applications of Cellophane Wrapping Machines

Cellophane wrapping machines are widely used across various sectors:

- **Food Industry**: They are commonly used for wrapping candies, chocolates, baked goods, and other perishable items, ensuring freshness and hygiene.

- **Pharmaceuticals**: Cellophane is used to wrap medicine bottles, blister packs, and other healthcare products, providing protection and visibility.

- **Consumer Goods**: Products such as cosmetics, soaps, and gift items benefit from cellophane wrapping, enhancing their marketability.

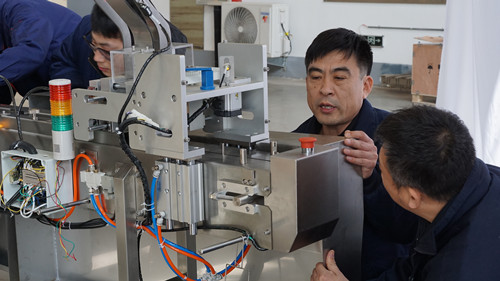

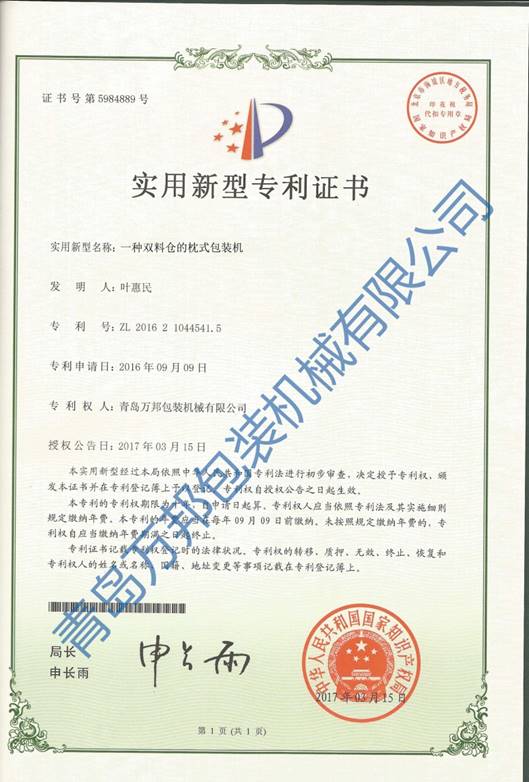

Technology advantage: *Strong R&D We have senior technical staff, continue to innovate products, continuously optimize product performance according to user feedback, and apply for new patents every year *Strict Q&C We attach great importance to the installation details of the product, even a small screw cannot be used wrongly. After installation, the company has repeated tests and can only leave the factory after reaching the standard that you are satisfied with. *GMP standard All of our machine is suitable GMP standard *Overseas designer consultation Excellent foreign technical engineers provide us with technical guidance.To make sure that we are the top manufacture for overwrapping machine

Culture advantages: Become a globally influential brand Provide customers with the best packaging solution Integrity cooperation, win-win situation A strong corporate culture, let us gather our strength, work together, build our own brand Wanbon, and maintain our original intention, so that we can always be

Company advatanges:More than 20 years experience, more than 50 patents,Member of China Packaging Industry Association,famous brand in China

Product advantage *Fully automatic: advanced software of PLC control system,Servo linkage, more accurate,one machine has 2 servo motor to 7 servo motor. *High speed Machine working stable,normally speed from 30-60 package/min.Actural speed depends on carton size and machine mode.The efficiency can be 95% or more. Very low failure rate and stable operation, bringing continuous and efficient benefits to customers *Easy to operate We can set up several packaging plans.When you want to change the carton box,just Call the corresponding plan.very easy.If connect with front and back machine, our machine no need worker.It can work smoothly. *Easy to change mold It will take 15-30 minitues to change mold *Long service life The machine can use more than 20 years.

CONTACT US

LEAVE US A MESSAGE

Wanbon Machinery is the top one in the field of over wrapping packaging machine and pillow type packaging machine in China.If you have other questions, please write to us. just tell us your requirements, we can do more than you can imagine.

Recommended