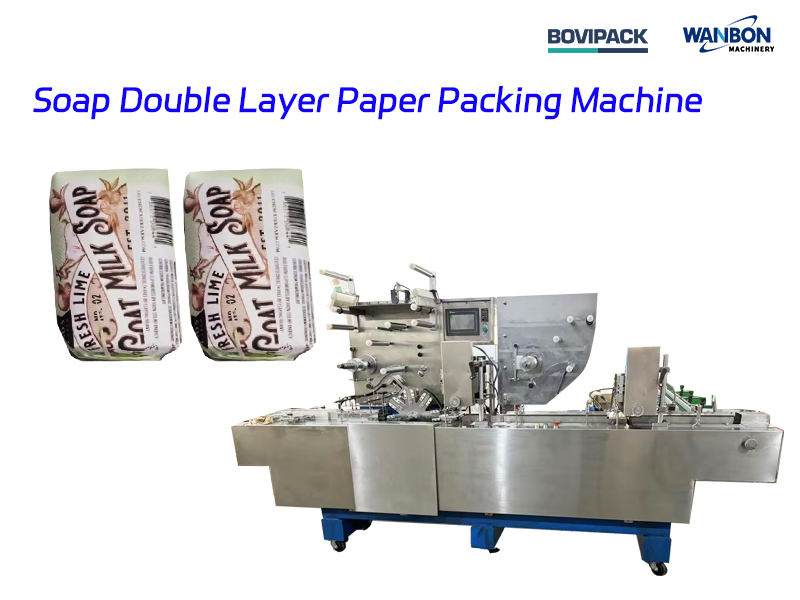

In the modern manufacturing landscape, efficiency and quality are paramount. The soap industry, with its diverse range of products and increasing consumer demand, requires advanced packaging solutions. One such innovative solution is the Soap Double Layer Paper Packing Machine. This machine is designed to enhance the packaging process, ensuring that soap products are not only well-protected but also aesthetically appealing to consumers.

Soap Double Layer Paper Packing Machine Machine Application

This machine is widely used in soap packing industry. It can play the role of moisture-proof, dust-proof and anti-counterfeiting, which is conducive to improving the packaging grade of products and increasing the added value of products.

Features of the Soap Double Layer Paper Packing Machine

1. **Double Layer Packaging**: As the name suggests, this machine utilizes a double layer of paper for packing. This feature provides enhanced protection against moisture and external contaminants, ensuring that the soap retains its quality during storage and transportation.

2. **High-Speed Operation**: The Soap Double Layer Paper Packing Machine is engineered for high-speed performance, significantly increasing production efficiency. It can pack a large number of soap bars in a short period, meeting the demands of large-scale manufacturing.

3. **Versatility**: This machine is versatile and can accommodate various soap sizes and shapes. Whether the soap is rectangular, oval, or custom-shaped, the machine can be adjusted to ensure a perfect fit.

4. **User-Friendly Interface**: Equipped with an intuitive control panel, the machine allows operators to easily set parameters, monitor production, and troubleshoot issues. This user-friendly design minimizes downtime and enhances productivity.

5. **Eco-Friendly Materials**: With a growing emphasis on sustainability, the Soap Double Layer Paper Packing Machine uses biodegradable and recyclable paper materials. This aligns with the industry's move towards environmentally friendly packaging solutions.

6. **Quality Control**: The machine incorporates advanced quality control mechanisms to ensure that each package is sealed properly. This reduces the risk of product damage and enhances customer satisfaction.

Benefits of Using a Soap Double Layer Paper Packing Machine

- **Cost-Effective**: By automating the packing process, manufacturers can reduce labor costs and minimize errors associated with manual packing. This leads to significant cost savings in the long run.

- **Enhanced Product Appeal**: The double layer of packaging not only protects the soap but also enhances its visual appeal. Attractive packaging can influence consumer purchasing decisions and boost sales.

- **Increased Shelf Life**: The protective layers help extend the shelf life of soap products by preventing moisture absorption and contamination. This is particularly important for natural soaps that may have a shorter shelf life.

- **Improved Brand Image**: Using high-quality packaging reflects positively on the brand. Customers are more likely to trust and choose products that are well-packaged and presented.

The Soap Double Layer Paper Packing Machine represents a significant advancement in the soap manufacturing industry. By combining efficiency, versatility, and eco-friendliness, this machine addresses the packaging challenges faced by manufacturers today. As the demand for high-quality soap products continues to rise, investing in such innovative packaging solutions will be crucial for businesses aiming to stay competitive in the market. The future of soap packaging is here, and it is both practical and sustainable.

CONTACT US

LEAVE US A MESSAGE

Wanbon Machinery is the top one in the field of over wrapping packaging machine and pillow type packaging machine in China.If you have other questions, please write to us. just tell us your requirements, we can do more than you can imagine.

Recommended