BOVIPACK: The Packing Requirements of the Overwrapping Machine

1. Product Size and Shape: The overwrapping machine is designed to accommodate specific product sizes and shapes.

It is essential to ensure that the products intended for overwrapping are within the machine's specified dimensions.

Irregularly shaped or oversized products may not fit properly, resulting in improper wrapping and sealing.

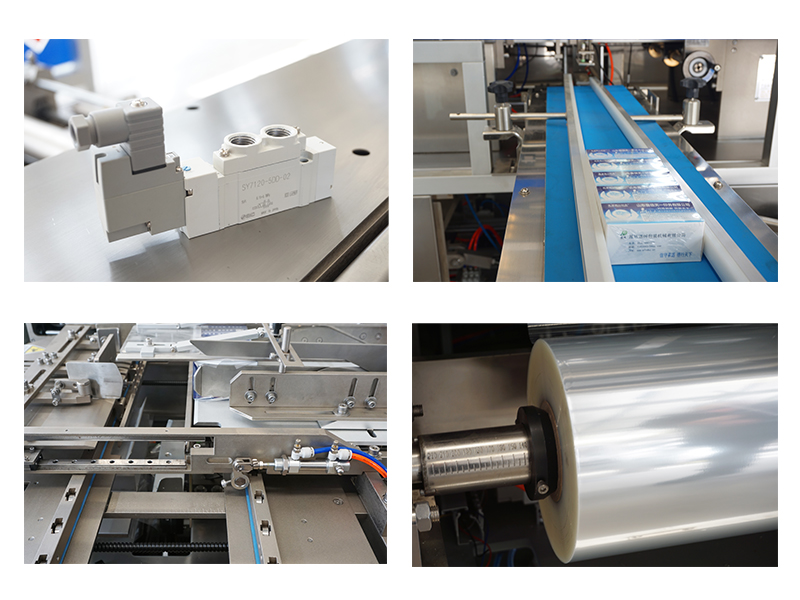

2. Packaging Material: The Bopp overwrapping machine requires the use of suitable packaging materials such as plastic film or foil.

The material should be compatible with the machine's specifications, ensuring smooth operation and optimal wrapping results.

The thickness and quality of the packaging material should also be considered to provide adequate protection to the packaged goods.

3. Product Orientation: Proper product orientation is necessary for efficient overwrapping.

The products should be placed on the machine's conveyor or feeding system in the correct orientation to ensure accurate wrapping and sealing.

Incorrectly oriented products may lead to misalignment, wrinkling, or incomplete sealing, compromising the packaging quality.

4. Product Stability: The overwrapping machine requires stable products to achieve consistent wrapping results.

Unstable or loosely placed products may shift during the wrapping process, leading to unevenly wrapped packages or even machine malfunctions.

It is crucial to ensure that the products are properly positioned and secured to maintain stability throughout the wrapping process.

5. Speed and Output: The cellophane overwrapping machine has specific speed and output capabilities.

The packing requirements include matching the machine's speed with the production line's requirements to maintain a smooth workflow.

Overloading the machine or operating it at a speed beyond its capacity can lead to decreased efficiency, increased downtime and potential damage to the machine.

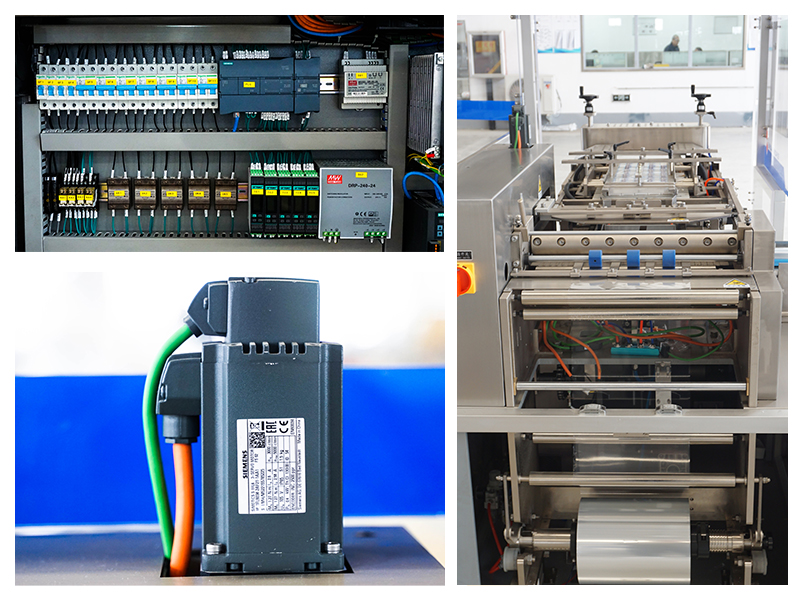

6. Sealing Temperature and Pressure: The overwrapping machine utilizes heat sealing to seal the packaging material.

It is essential to set the appropriate sealing temperature and pressure based on the packaging material and product requirements.

Insufficient sealing temperature or pressure may result in weak seals, while excessive temperature or pressure may damage the packaging material or the product itself.

7. Maintenance and Cleaning: Regular maintenance and cleaning are essential for the optimal functioning of the overwrapping machine.

Following the manufacturer's guidelines for maintenance, lubrication and cleaning is crucial to ensure longevity and reliability.

Proper maintenance practices help prevent breakdowns, reduce downtime and maintain consistent packaging quality.

In conclusion, the Overwrapping Machine has specific packing requirements that need to be met to ensure efficient and effective operation.

These requirements include product size and shape, suitable packaging material, proper product orientation, stability,

matching speed and output, sealing temperature and pressure, as well as regular maintenance and cleaning.

These are the packaging requirements summarized by BOVIPACK.

By adhering to these requirements, businesses can maximize the performance of their overwrapping machines and ensure high-quality packaging for their products.