Cartoning for medicine plate is a crucial process in the pharmaceutical industry. It involves packaging medicine plates into cartons for distribution and sale. This process ensures that the medicine plates are protected from damage and contamination during transportation and storage.

Automatic Cartoning Box Machine Features

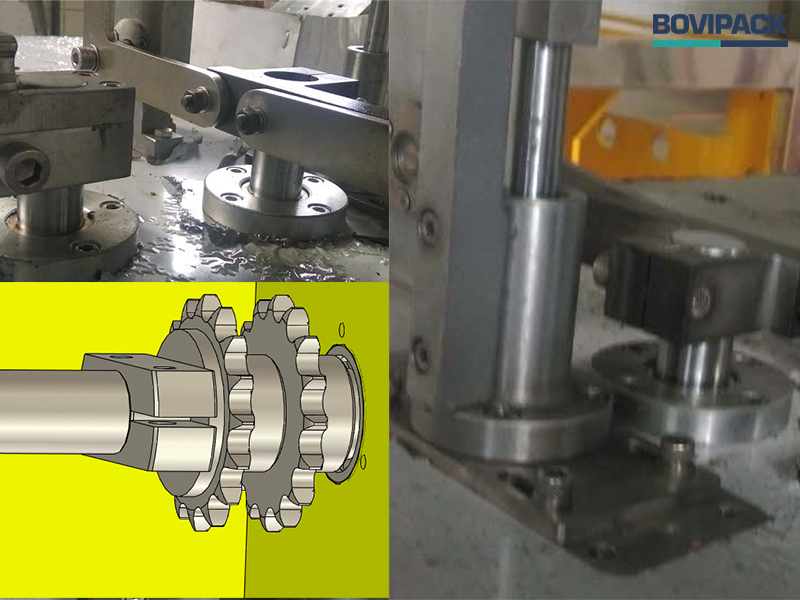

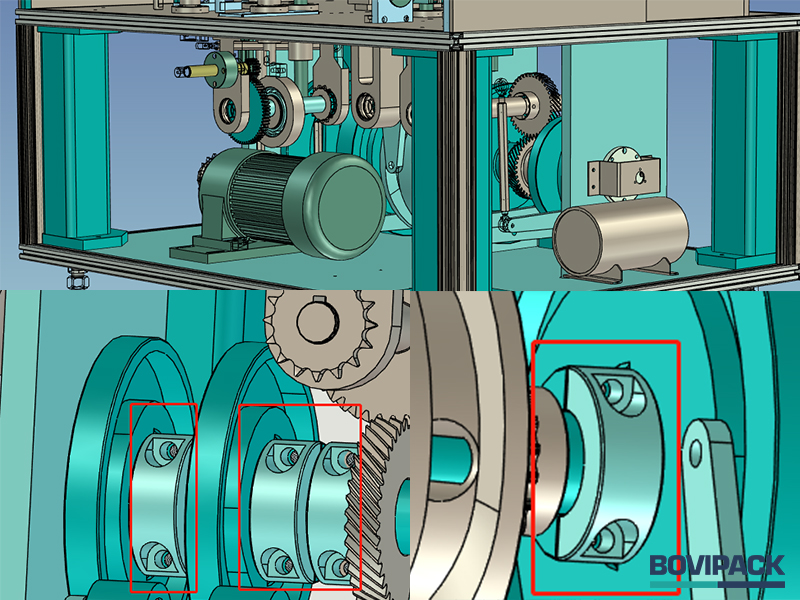

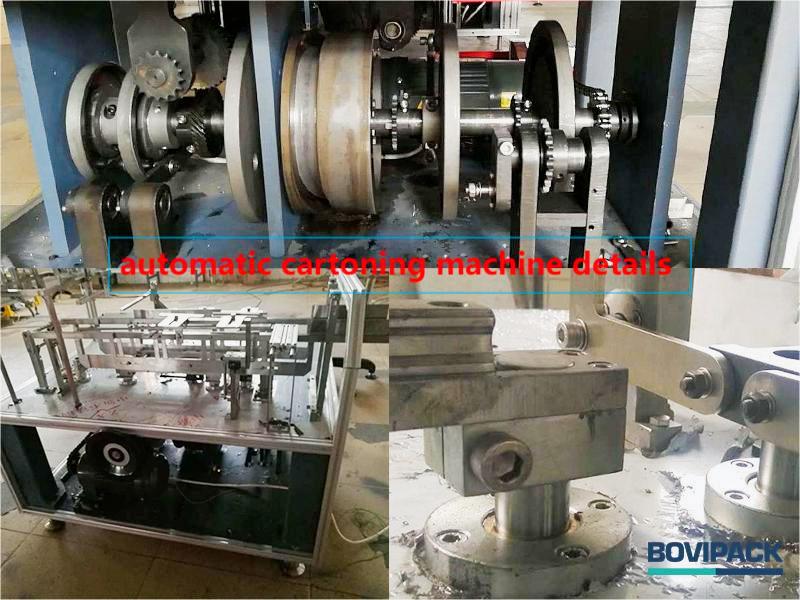

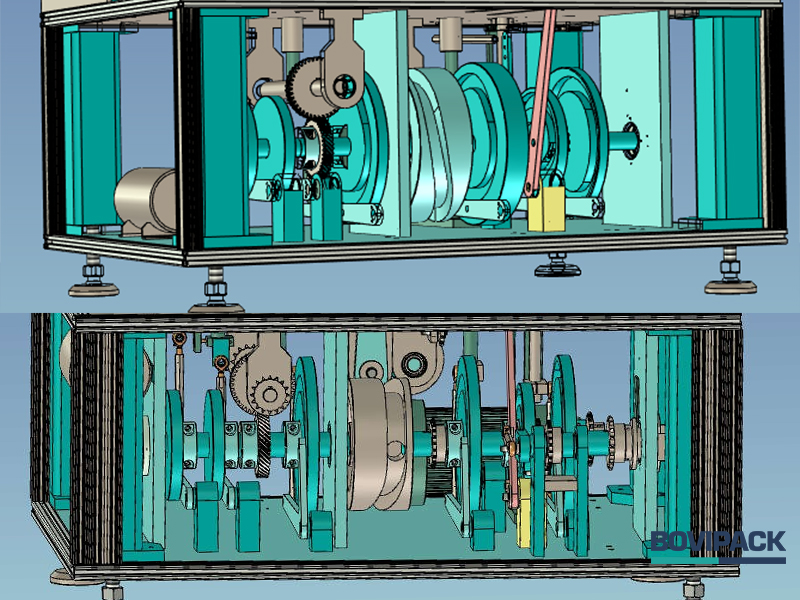

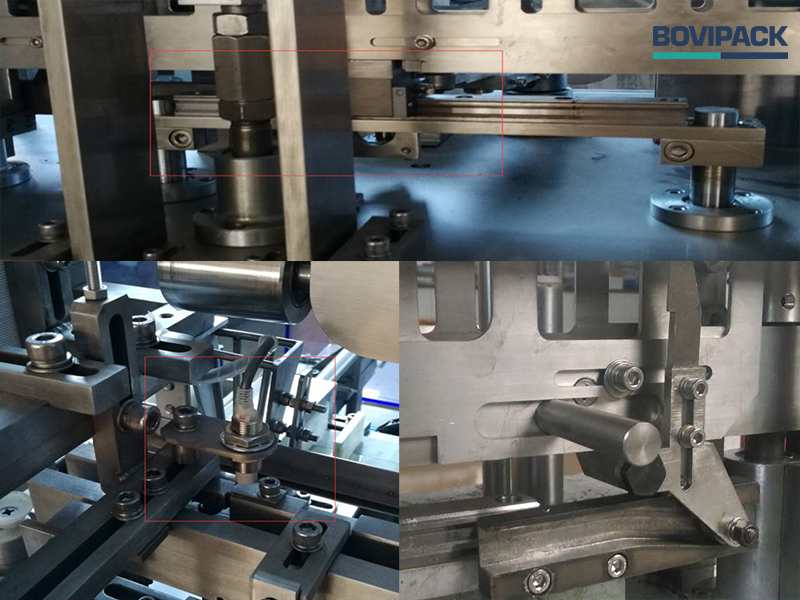

1. The box filling machine can automatically complete the folding, assembly and sealing of the box to improve production efficiency.

2. The box filling machine can be adjusted according to the size and shape of the product, and is suitable for different types of boxes.

3. The advanced control system can realize accurate positioning and operation to ensure the accuracy and stability of product packing.

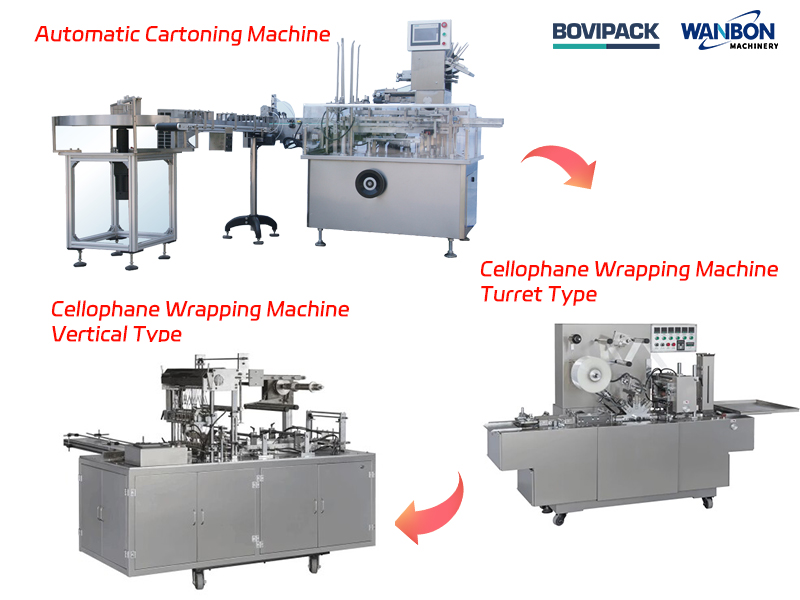

4. The packing machine can be seamlessly connected with other production lines to achieve automated production lines.

5. The box packing machine has multiple safety protection devices to ensure the safety of operators and equipment.

Cartoning for medicine plates is essential for maintaining the quality and integrity of the medication. Medicine plates are fragile and can easily break or become contaminated if not properly packaged. Cartoning provides a protective barrier that prevents the medicine plates from being damaged by external factors such as moisture, light, and temperature fluctuations. This helps to ensure that the medication remains safe and effective for the end user.

The process of cartoning for medicine plates involves several steps. First, the medicine plates are inspected for any defects or damage. This is done to ensure that only high-quality plates are packaged for distribution. Next, the plates are loaded into the cartoning machine, which folds and seals the cartons around the plates. The cartons are then labeled with important information such as the name of the medication, dosage instructions, and expiration date.

Cartoning for medicine plates also plays a crucial role in ensuring compliance with regulatory requirements. Pharmaceutical companies are required to adhere to strict guidelines set by regulatory authorities to ensure the safety and efficacy of their products. Cartoning helps companies to meet these requirements by providing a tamper-evident seal that shows if the carton has been opened or tampered with. This helps to prevent the distribution of counterfeit or substandard medication. In addition to protecting the medication, cartoning for medicine plates also helps to improve the efficiency of the distribution process. By packaging the plates into cartons, companies can streamline the packing and shipping process, making it easier to transport the medication to pharmacies and healthcare facilities. This can help to reduce the risk of errors and delays in the distribution chain, ensuring that patients receive their medication in a timely manner.

In addition to protecting the medication, cartoning for medicine plates also helps to improve the efficiency of the distribution process. By packaging the plates into cartons, companies can streamline the packing and shipping process, making it easier to transport the medication to pharmacies and healthcare facilities. This can help to reduce the risk of errors and delays in the distribution chain, ensuring that patients receive their medication in a timely manner.

Overall, cartoning for medicine plates is a critical process in the pharmaceutical industry. It helps to protect the medication from damage and contamination, ensure compliance with regulatory requirements, and improve the efficiency of the distribution process. By investing in high-quality cartoning equipment and processes, pharmaceutical companies can ensure that their products reach patients safely and effectively.

CONTACT US

LEAVE US A MESSAGE

Wanbon Machinery is the top one in the field of over wrapping packaging machine and pillow type packaging machine in China.If you have other questions, please write to us. just tell us your requirements, we can do more than you can imagine.

Recommended