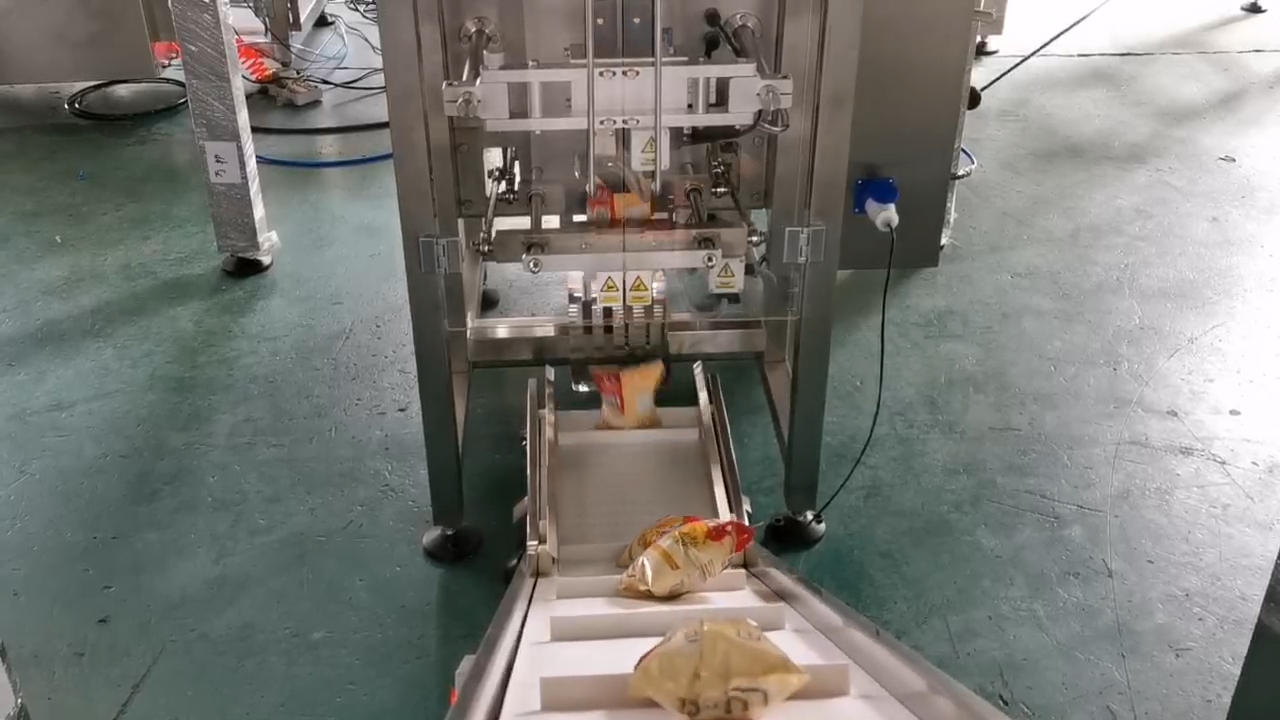

Our potato chips VFFS packaging machines are equipped with advanced features to ensure efficient and precise filling, sealing, and packaging.

This VFFS machine is suitable for automatic nitrogen filled plantain potato banana tomato cassava corn tortilla chips, crisps, fully auto packaging machines.

Perfect packing effects and enough nitrogen.

Products Description

Potato chips VFFS (Vertical Form Fill Seal) packaging machines are specialized equipment designed to automatically form, fill, and seal bags of potato chips. These machines use a continuous roll of packaging film to create bags, fill them with a precise amount of potato chips, and then seal the bags for distribution and sale. The VFFS machine process begins with the unwinding of the packaging film, which is then formed into a tubular shape. The potato chips are dispensed into the formed bags, and the machinery seals the bags, usually with heat sealing technology. The finished bags are then cut and discharged from the machine, ready for packaging and shipping.

|  |

Key features of our potato chips VFFS packaging machines

1. Accurate Filling: Our vertical form fill seal machine ensures precise measurement and filling of potato chips into pouches, minimizing product waste and ensuring consistent packaging.

2. Product Preservation: The packaging process is designed to protect the quality and freshness of your potato chips, extending their shelf life and maintaining their crunchiness.

3. User-friendly Operation: Easy-to-use control panels and intuitive interfaces make operating our machines simple and hassle-free, reducing downtime and increasing productivity.

4. Robust Construction: Our vertical pouch packing machines are built with high-quality materials to withstand continuous operation in demanding production environments, ensuring longevity and durability.

5. Versatile Packaging Options: Our VFFS machines offer various packaging options, including pillow bags, gusseted bags, and stand-up pouches, allowing for flexibility in your product presentation.

As a trusted vffs packaging machine manufacturer, we prioritize customer satisfaction and provide comprehensive after-sales support, including installation, training, and maintenance services. Get in touch with us today to discuss your potato chips vertical form fill seal machine requirements and elevate your packaging efficiency and product quality.

Nitrogen Filling Effect

FAQ:

1. Why VFFS packaging machines is filling nitrogen? not oxygen?

Some consumers get annoyed by all that “air” in their bag of chips. But that air isn't air at all. If it were, it wouldn't take long for your potato chips to spoil and for their taste to deteriorate.

The reason is that the ambient air surrounding us contains 78% nitrogen but also has an oxygen content of 21%. This makes it perfect for breathing but less ideal to come into contact with potato chips and other foods. That’s because the oxygen reacts with ingredients such as the oil in potato chips and breaks them down. This reduces the shelf life of a lot of different foods.

To address this problem, you first need high-quality nitrogen to displace the air in the chip bag. Why nitrogen? Because it is an inert gas, which means it reacts poorly with other chemical substances.

Oxygen, on the other hand, is highly reactive and reacts with other molecules. This leads to food spoiling or losing its freshness. The VFFS packaging machines solution to this problem is a process called “modified atmosphere packaging.” Here, the ambient air in food packaging is replaced with a mixture containing mostly nitrogen. While you may not know the science behind it, you are probably doing something similar already. Are you resealing your bags of potato chips after you open them to keep them from going stale? Then you are trying to protect them from exposure to oxygen.

2. What are the advantge of VFFS packaging machines for snack?

1. Versatility: VFFS machines can efficiently package a wide variety of snack products, such as chips, nuts, candies, and other snack items in various shapes and sizes.

2. Efficiency: The vffs packaging machines are known for their high-speed packaging capabilities, which can help snack manufacturers increase their production output and meet market demands.

3. Flexibility: VFFS machines can accommodate different types of packaging materials, allowing for options such as flexible film, laminates, and barrier films to suit the specific needs of snack packaging.

4. Product protection: Vertical pouch packing machine can provide hermetic sealing, ensuring that snacks are well-protected from external factors such as moisture, air, and contaminants, thus preserving their freshness and quality.

CONTACT US

LEAVE US A MESSAGE

Wanbon Machinery is the top one in the field of over wrapping packaging machine and pillow type packaging machine in China.If you have other questions, please write to us. just tell us your requirements, we can do more than you can imagine.

Recommended